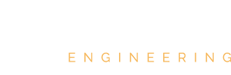

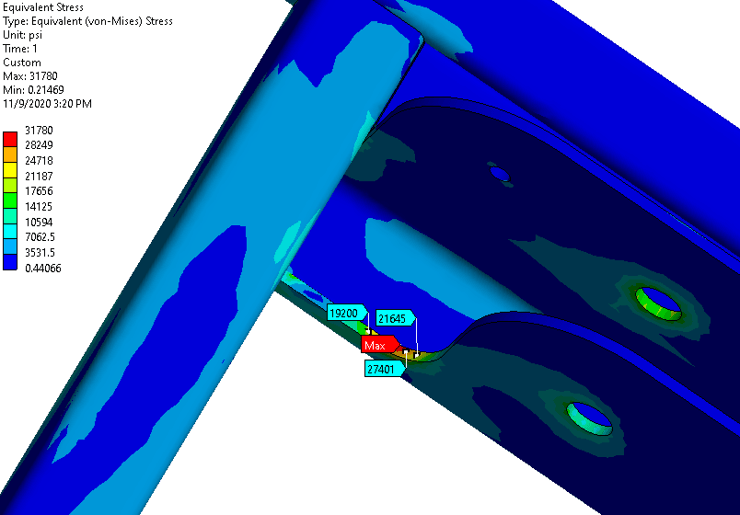

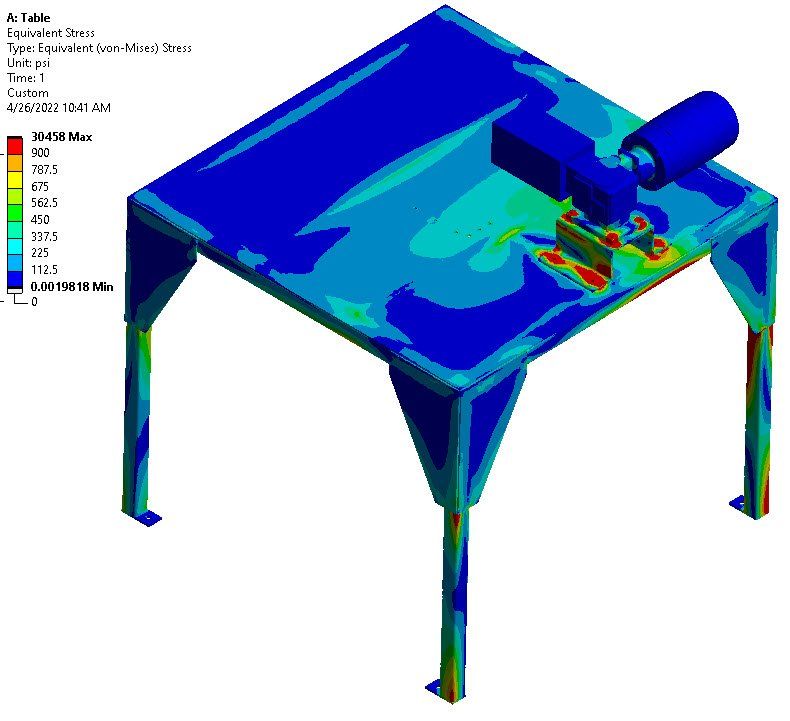

Maintain Structural Integrity

Ensure Reliability and Durability

Optimize Design

Capabilities

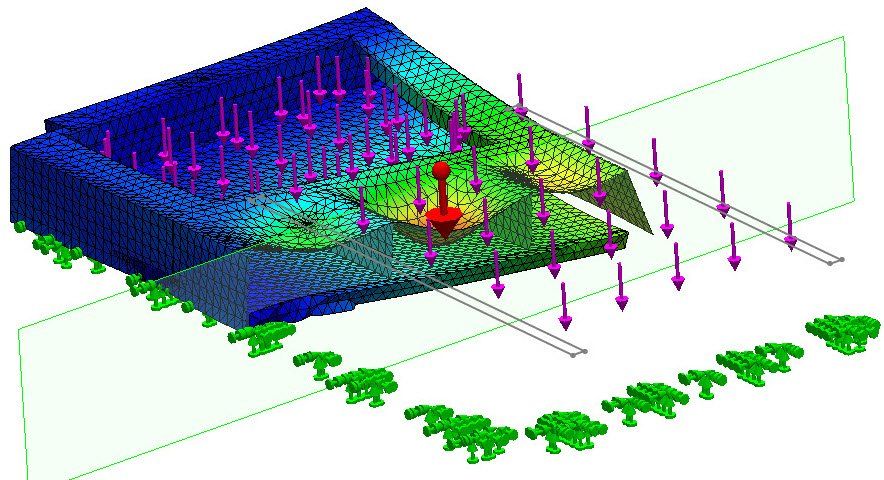

We utilize a combination of hand calculations and Finite Element Analysis (FEA) in ANSYS engineering software to optimize designs, reduce weights and costs, and ensure part performance.

Analyze Structural Stresses in Parts & Materials

We verify components meet requirements early in the design cycle, saving you costly and time-consuming prototype iterations.

Johnston Engineering has extensive experience in advanced structural analysis. We perform Finite Element Analysis (FEA) to analyze all stresses, heat, and weight loads of your product or system.

Interested in an Analysis Quote?

We want to know your needs exactly so we can provide the perfect solution.