Mechanical Engineering

Turn your ideas into 3D models, and then into real, working products, devices and machines.

Mechanical Design & Engineering

We generate a 3D CAD model of your product, device or machine, then make fabrication drawings.

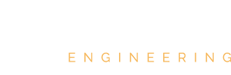

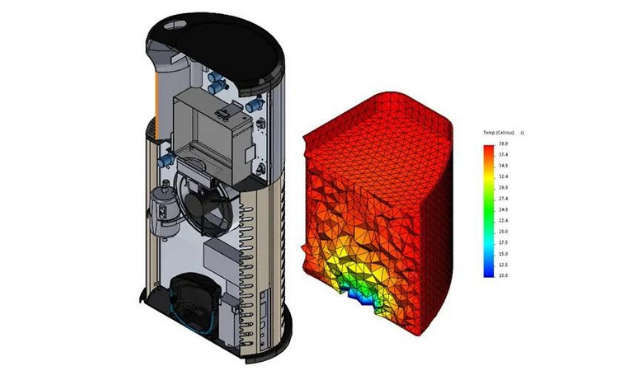

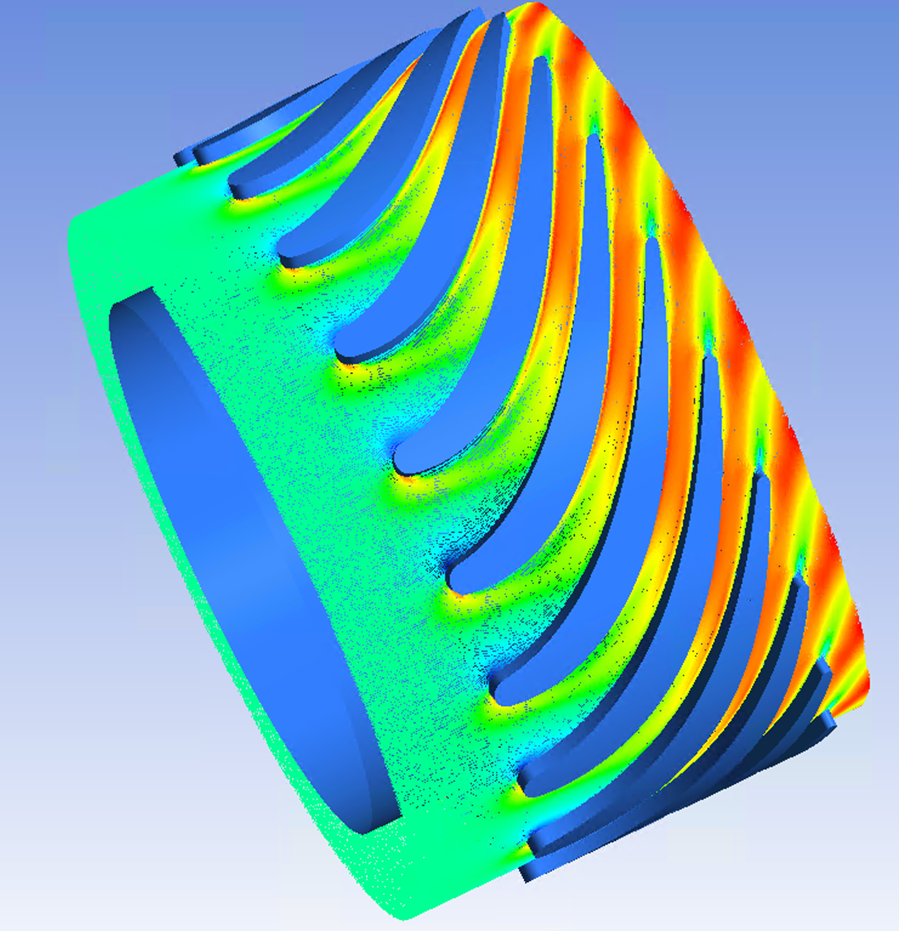

Physics-Based Simulations

We believe the best time to fail is on the computer during simulation, not during production.

Design for Manufacturability

We determine the best materials and fabrication processes to ensure your product is optimally designed for low or high-volume manufacturing.

Capabilities

From concept to creation - whether you're starting from an existing 3D CAD model or a napkin sketch, we can create, optimize and validate your design.

Capabilities

From concept to creation - whether you're starting from an existing 3D CAD model or a napkin sketch, we can create, optimize and validate your design.

Assembly & System Design

We have experience designing complex mechanical systems that incorporate multiple components and subsystems. This includes new machines and complex mechanical systems for industrial or commercial applications.

- Custom Machines & Devices

- Composite Material Assemblies

- Welded Structures

- Machined Components

- Custom Test Fixtures

- Thermal Management System Design

- Heat Exchanger Design

- Cold Plate Design

Component Design

We work within your requirements and specifications while optimizing for performance, manufacturability, and cost-effectiveness.

- Custom Part Design

- Consumer Products

- Medical, Dental & Bioscience Devices

- Firearms and Firearm Accessories

- Sports Equipment

- Agricultural and Food Processing

Analysis and Simulation

We perform physics-bases analyses to provide a detailed understanding of how a design will perform under various operating conditions.

- Thermal Management

- Finite Element Analysis

- Computational Fluid Dynamics

- Structural Analysis

- ANSYS

- Hand Calculations

Concept Development

We understand your goals and brainstorm the mechanical components and systems involved to turn your concept sketch into a fully formed design.

- Ideation

- Concept Selection

- Feasibility Study

- Design Optimization

Material Selection

We choose the best materials for a machine, product or component to ensure it meets its required function, durability, and reliability.

- Materials Research

- Experienced with Standard or Exotic Materials

- Stress and Thermal Analysis Using Custom Materials Properties

Design for Manufacturability and Assembly

We identify optimal manufacturing process and design with those manufacturing and assembly processes in mind, minimizing components, fabrications efforts, and ultimately cost.

- Assembly Design

- Prototype Design

- Component Design

- Production Design

Component Design

We work within your requirements and specifications while optimizing for performance, manufacturability, and cost-effectiveness.

- Consumer Products

- Medical, Dental & Bioscience Devices

- Firearms and Firearm Accessories

Assembly & System Design

We have experience designing complex mechanical systems that incorporate multiple components and subsystems. This includes new machines and complex mechanical systems for an industrial or commercial applications.

- Custom Machines & Devices

- Composite Material Assemblies

- Welded Structures

- Machined Components

- Custom Test Fixtures

- Thermal Management System Design

- Heat Exchanger Design

- Cold Plate Design

Concept Development

We understand your goals and brainstorm the mechanical components and systems involved to turn your concept sketch into a fully formed design.

- Ideation

- Concept Selection

- Feasibility Study

- Design Optimization

Analysis and Simulation

We perform physics-bases analyses to provide a detailed understanding of how a design will perform under various operating conditions.

- Thermal Management

- Finite Element Analysis

- Computational Fluid Dynamics

- Structural Analysis

- ANSYS

- Hand Calculations

Material Selection

We choose the best materials for a product or component to ensure it meets its required function, durability, and reliability.

- Materials Research

- Experienced with Standard or Exotic Materials

- Stress and Thermal Analysis Using Custom Materials Properties

Design for Manufacturability and Assembly

We identify optimal manufacturing process and design with those manufacturing and assembly processes in mind, minimizing components, fabrications efforts, and ultimately cost.

- Assembly Design

- Prototype Design

- Component Design

- Production Design

Core Software

Tailored Mechanical Design & Analysis Engineered Solutions

Ensure products, devices and machines meet specifications before anything gets built with our

process of

integrated design & analysis.

Project Management Services

We understand that successful projects require a diverse range of engineering disciplines, and mechanical engineering can be just one piece of the puzzle. At Johnston Engineering we are able provide a comprehensive team of proven experts, including electrical engineers, software engineers, physicists, and more. Our extensive network allows us to assemble a cohesive team that we manage, ensuring your project stays on schedule and on budget.

We provide turnkey project management from start to finish or can work as an extension of your team -

whatever you need to help drive the success of your project.

Turnkey Project Management

Whether starting from an existing 3D CAD model, or a napkin sketch, we can create, optimize, validate, and test your design. We manage the team, buy or fabricate hardware, and assemble and test your product.

- Concept Design. Ideation

- Mechanical Design. 3D CAD Modeling

- Advanced Thermal, Fluid-Flow, and Structural Analysis

- Material Selection

- Performance Testing

- Design for Manufacturability (DFM)

- Design for Assembly (DFA)

- Delivery, Assembly, and Test

Engineering Contracting

Hire Johnston Engineering as an extension of your team to stay on schedule and on budget.

- Instantly build a robust team without the commitment to hiring employees.

- Fill knowledge gaps in product design, fabrication, and engineering analysis including thermal, fluid-flow, and structural analysis.

- Produce the best possible product with the least number of iterations.

- Experience a quicker overall development process.

"How Businesses Save Time & Money By Contracting Engineering Firms" - Download PDF.

Why Choose Johnston Engineering?

True Expertise in Engineering Design & Analysis

At Johnston Engineering, our approach to new technology development and commercialization doesn't rely on endless prototype iterations. Instead, we leverage our advanced design and analysis capabilities to identify potential issues of product performance and manufacturability before proceeding to the build and testing stages, providing a more reliable approach to new technology development.

Andy Johnston P.E, President of Johnston Engineering, is considered a subject matter expert in Thermal Analysis, Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) and leads the Johnston Engineering analysis team.

We Understand the Business Side of Engineering

We understand your project doesn't have unlimited time and money and we work to secure timely and cost-effective solutions to move your project forward.

At Johnston Engineering we provide true integrated design and analysis capabilities that allows us to thoroughly evaluate product designs and identify potential issues before they become costly problems, allowing you to stay on-schedule and on-budget.

Combination of Experience in New Technology Development + Design for Manufacturability

With 100+ successful product development projects, Johnston Engineering has built a reputation for its expertise in providing innovative and reliable mechanical design solutions for new technologies.

Our ability to troubleshoot, test, and solve problems is further propelled by our understanding of the workings of the machines that manufacture your products, which comes from years of experience in fabrication.

We provide engineering solutions tailored to your product, device, or machine combined with a keen understanding of fabrication processes and materials to ensure your product meets all regulatory and performance requirements while optimizing cost-effectiveness.

Interested in Mechanical Engineering Services?

We want to know your needs exactly so we can provide the perfect solution.