Commercial Building Carbon Capture Device Engineering Design & Analysis

Johnston Engineering assisted with the research commercialization, design, Finite Element Analysis (FEA), and Computational Fluid Dynamics (CFD) to successfully develop a decarbonization device meant for use in commercial buildings, for our client Carbon Quest.

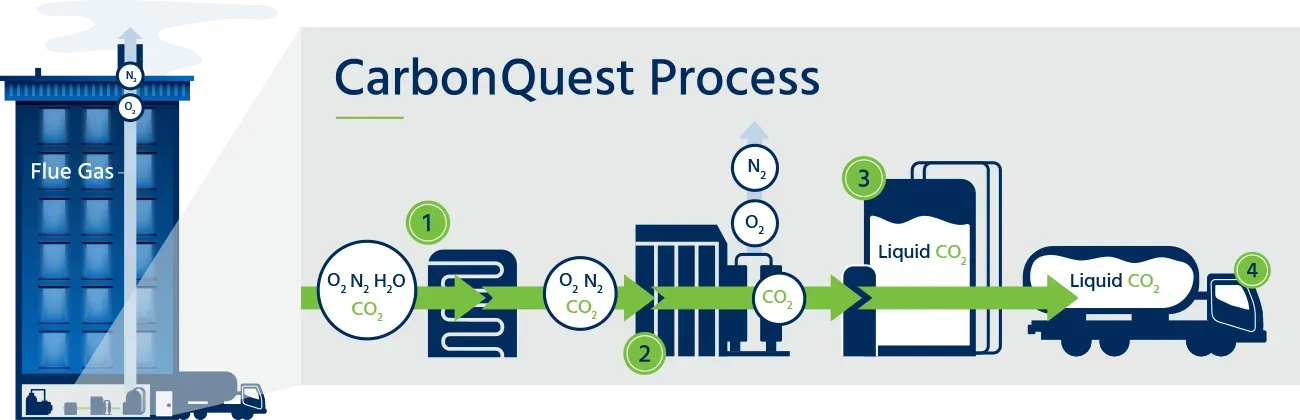

CarbonQuest has developed a modular system that allows for the capture and liquefaction of CO2 on-site. "This recycled CO2 is then made available to off-takers who can use it in a variety of environmentally beneficial ways, such as in the production of concrete or as a replacement for petroleum in jet fuel and chemical processes. By implementing this innovative system, building owners and operators can now enjoy a new revenue stream while simultaneously ensuring compliance with emissions guidelines" - Carbon Quest.

Our Contribution:

Johnston Engineering provided mechanical engineering design, thermal analysis, two-phase pressure drop analysis, component sourcing, build and testing services. We provided design, modifications, operation, and data processing of a research and development test fixture to characterize CO2 absorbent performance in a pressure swing absorption cycle.

- Mechanical Design

- Mechanical Engineering

- Convection Thermal Analysis

- Two-phase pressure drop analysis

- Material Sourcing

- Material Ordering

- Product Assembly

- Product Test

The purpose of the CO2 absorbent performance R&D test fixture was to characterize the performance of various candidate absorbents for use in a pressure-swing absorption cycle to concentrate CO2 gas. A P&ID diagram of the test fixture was created to identify all components in the system. Characteristic equations were developed to quantify system and key component uncertainties such as mass flow of CO2 in mixed gas flow, and total mass flow of CO2 leaving the system. 3D CAD files were generated in SOLIDWORKS and reviewed with the customer to ensure the proper design intent was met. Pressure, flow and temperature sensors were selected, then we built the system and wrote the LabVIEW data acquisition code. We performed test, data reduction and data analysis on a number of absorbents. The test result was highly improved CO2 concentration performance.

In another portion of the development, Johnston Engineering worked with CarbonQuest on the two-phase pressure drop in a line containing flowing liquid CO2 and noncondensable gas. CarbonQuest needed to know the pressure drop in this line to ensure proper system operation. Calculation during two-phase flow requires additional work compared to single-phase flow. REFPROPS data was used for fluid properties and the Martinelli Nelson parameter was used for Turbulent vapor Turbulent liquid flows assuming the separated flow model. The Chisholm and Laird two-phase multiplier was used in the calculation to relate the frictional component of a two-phase pressure drop to a single-phase pressure drop at the same mass flow rate to calculate the overall line pressure drop. All engineering efforts were made on behalf of Carbon Quest and their new patented, ground-breaking technology.

To learn about Carbon Quest's industry-changing technology, we encourage you to learn more on CarbonQuest.com