Leverage Our Expertise

Select materials and perform analysis to ensure components withstand stresses.

Test Your Design

See, hold, feel, and test your products before committing to

high-volume manufacturing.

Move Forward With Confidence

Design for manufacturing, assembly or optimize for next iterations.

How We Help

We design a 3D CAD model of your idea, select appropriate materials, and fabricate, deliver, and test your prototype.

Design a 3D CAD Model

We work with you to create a Computer-Aided Design (CAD) Model of your product using SolidWorks 3D CAD software.

Select Appropriate Materials

We choose the best materials for your prototype, based on factors such as cost, strength, and durability.

Create Detailed Technical Drawings

We create detailed technical drawings that can be used by the manufacturer to produce the prototype.

Perform Finite Element Analysis (FEA)

We test the strength and durability of the design, ensuring that it can withstand the stresses and strains it will be subjected to in use.

Fabrication and Assembly

After designing and simulation testing, we quote and order parts from fabrication shops and assemble the prototype.

Performance Testing

After assembly we physically test your prototype, testing how well the product performs under different conditions and real world stresses.

Design for Manufacturability

We optimize the design for ease of manufacturing on whichever machine it will be made on, making it more cost-effective, efficient and repeatable to produce.

How We Help

We design a 3D CAD model of your idea, select appropriate materials, and fabricate, deliver, and test your prototype.

Design a 3D CAD Model

We work with you to create a Computer-Aided Design (CAD) Model of your product using SolidWorks 3D CAD software.

Select Appropriate Materials

We choose the best materials for your prototype, based on factors such as cost, strength, and durability.

Create Detailed Technical Drawings

We create detailed technical drawings that can be used by the manufacturer to produce the prototype.

Perform Finite Element Analysis (FEA)

We test the strength and durability of the design, ensuring that it can withstand the stresses and strains it will be subjected to in use.

Fabrication and Assembly

After designing and simulation testing, we quote and order parts from fabrication shops and assemble the prototype.

Performance Testing

After assembly we physically test your prototype, testing how well the product performs under different conditions and real world stresses.

Design for Manufacturability

We optimize the design for ease of manufacturing on whichever machine it will be made on, making it more cost-effective, efficient and repeatable to produce.

Prototyping Methods

Whether you are looking for a

proof of concept prototype or a

pre-production prototype, we design parts and help you pick the best materials and manufacturing processes to

ensure your prototype and eventual product will be successful.

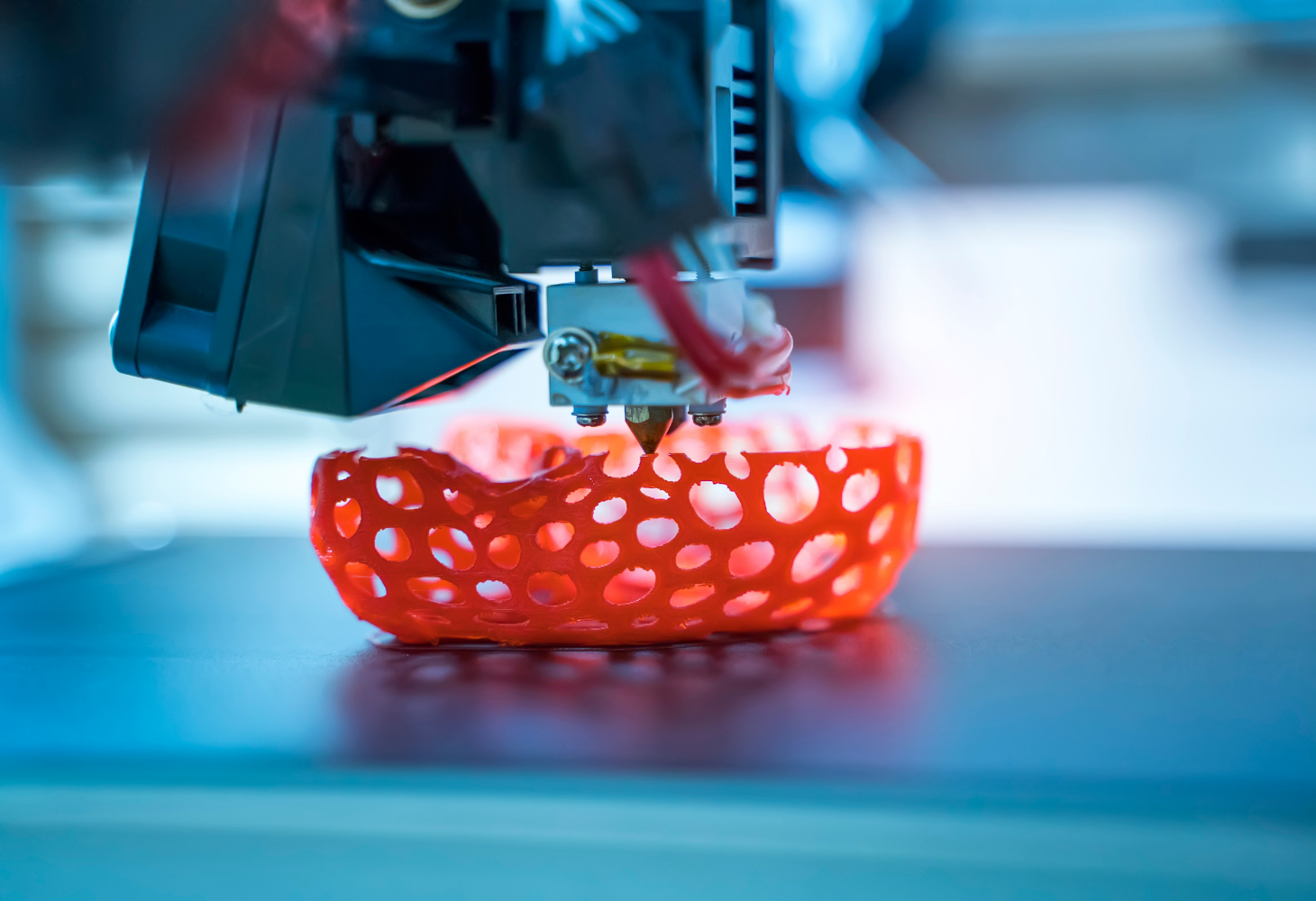

3D Printing

Additive Manufacturing. Build preproduction prototypes and custom parts with 3D Printing.

CNC Machining

Create complex and precise parts with the least number of machining setups.

Sheet Metal Fabrication

Cut, form, roll and bend flat sheets of metal to your design.

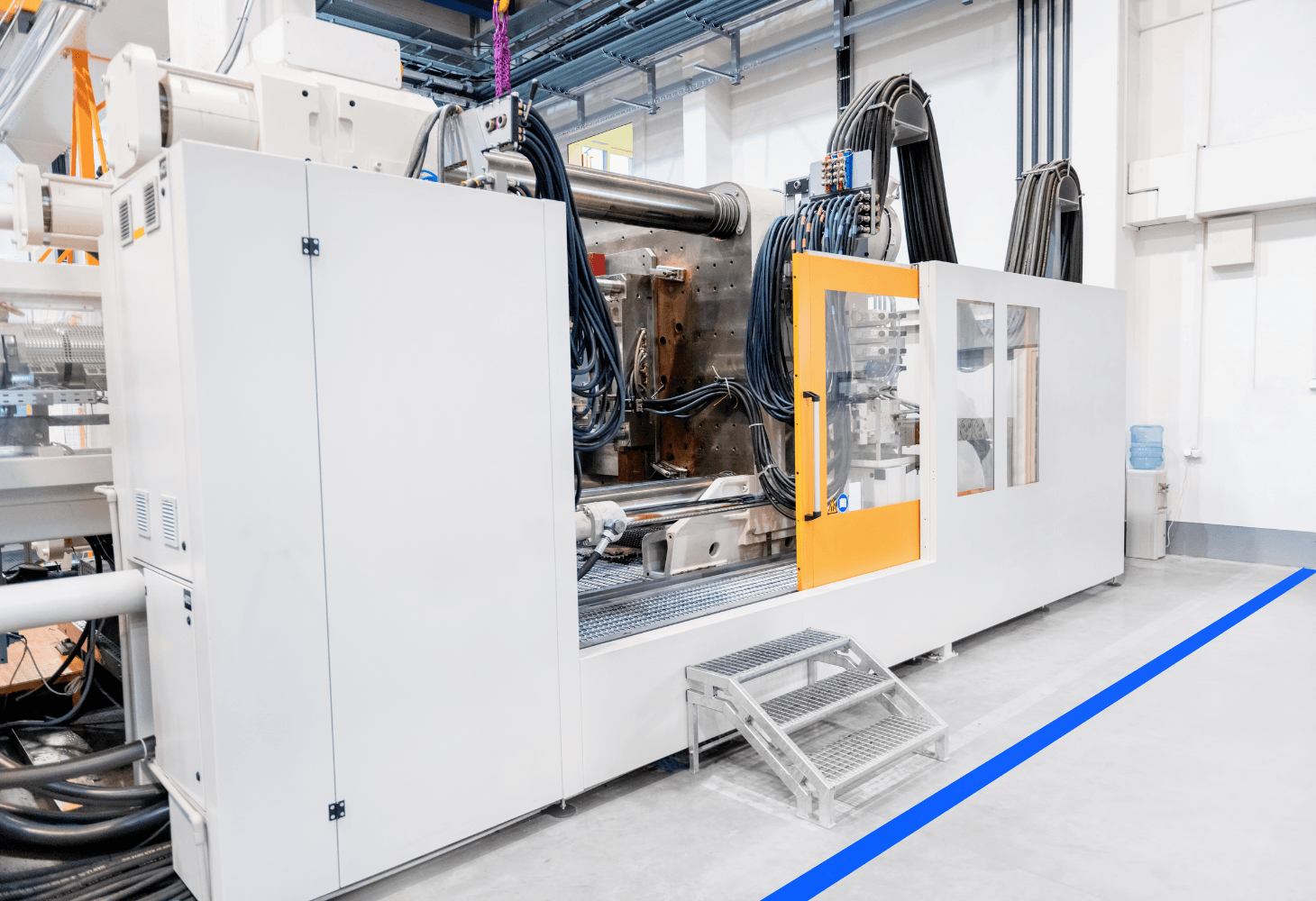

Injection Molding

Prototype Injection molds allow moderate production volumes at a low price.

Welding

Join metals to create structural weldment parts and assemblies.

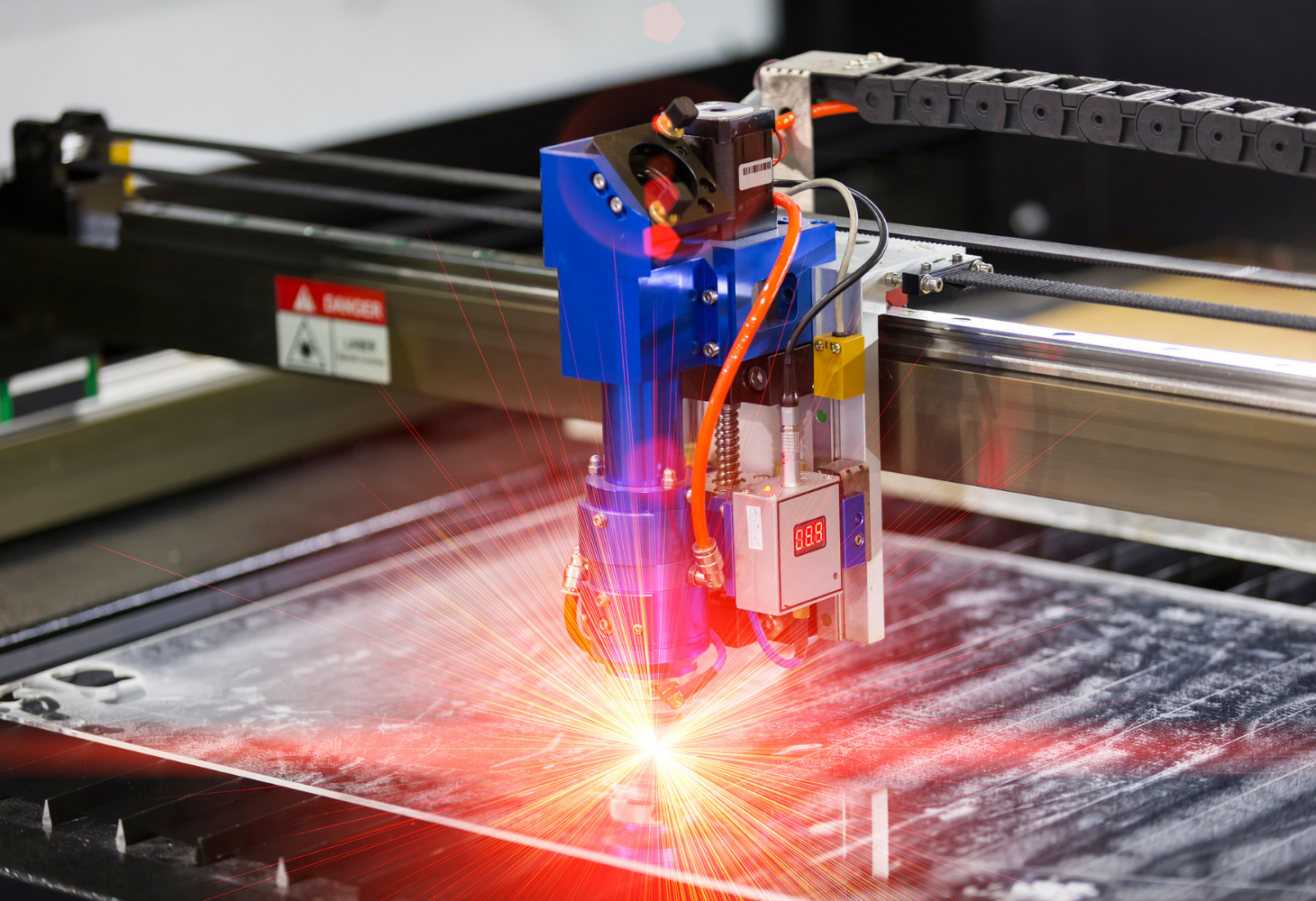

Laser Cutting

Cut and shape thin metal precisely and quickly.

Water Jet Cutting

Cut and shape a wide range of materials with no heat-affected zone.

Off the Shelf Assembly

Identify and order existing parts from hardware and industrial material suppliers to incorporate into your design.

Effective Prototyping

vs Rapid Prototyping

Our method of Effective Prototyping involves performing upfront analysis and testing on a digital prototype before anything gets built.

We identify potential issues early on and make necessary adjustments before moving forward with production,

saving you time and money.

"The best time to fail is on the computer during simulation."

Interested in Fabricating a Prototype?

We fabricate and deliver your prototype in a timely matter and at a competitive price.

© 2023 Johnston Engineering. All rights reserved. Website by Limelyte Technology Group, Inc.